In response to changing market expectations, manufacturers everywhere are feeling more and more pressure to improve operational efficiency and agility.

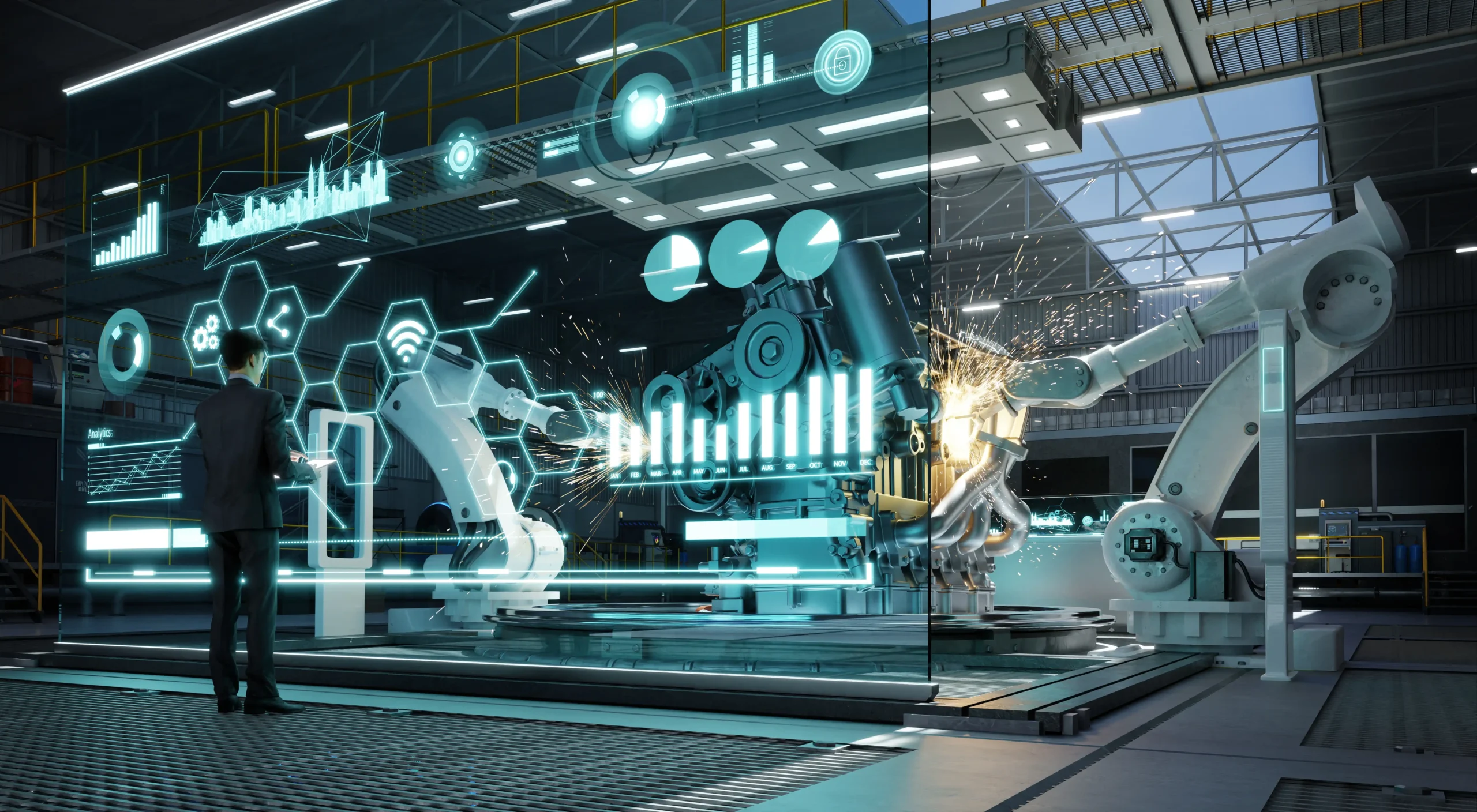

The U.S. National Institute of Standards and Technology (NIST) reports that manufacturers are using operational dashboards more and more to track key performance indicators (KPIs) in real time. This allows for quality control, proactive maintenance, and throughput optimization. Dashboards are essential to smart manufacturing projects because they increase shop floor response and offer visibility across several systems.

According to McKinsey, manufacturing digital transformation can increase worker productivity by 15% to 30%. Increased automation of manual processes, more operational transparency, and AI-supported decision-making are a few possible ways to achieve this productivity improvement.

However, there are new difficulties associated with the transition from manual to digitalized systems. Standardized data sources, scalable infrastructure, and interoperable systems that can enable real-time edge computing are necessary for the shift to simulation dashboards.

These difficulties are made worse by the fact that many firms continue to encounter data obstacles. Just 12% of organizations say they have data that is accessible and of high enough quality to support successful AI implementation, according to research from data integrity leader Precisely in collaboration with the Center for Applied AI and Business Analytics at Drexel University’s LeBow College of Business (Drexel LeBow).

However, compared to 50% in 2023, 64% of respondents named data quality as their greatest data integrity concern. These pervasive discrepancies between integrity and accessibility and data needs highlight the challenges manufacturers now face in promoting successful and fast AI integration.

On the “AI in Business” podcast, editorial director Matthew DeMello recently spoke with Mike Geyer, Director of AI for Industrial at NVIDIA, and Rad Desiraju, Corporate Vice President of Manufacturing at Microsoft, about how manufacturers can get past these obstacles and fully utilize digital twins.

Data interoperability, infrastructure scaling, and the usefulness of simulation dashboards were among the subjects they discussed. Mike and Rad both underlined how crucial GPU-accelerated edge computing and integrated platforms are to advancing manufacturing’s operational effectiveness, safety, and predictive capabilities.

Two important takeaways for manufacturing executives from their discussion are examined in this article:

- Using 3D digital twins to advance manufacturing intelligence: Real-time simulation analysis is made possible by switching from conventional monitoring dashboards to generative AI-driven 3D digital twins. This improves decision-making for increased operational agility, safety, and throughput.

- Creating scalable, interoperable infrastructure: Using GPU-accelerated platforms to lower latency, enhance data interoperability, and speed time-to-value; standardizing various data sources; and implementing containerized edge computing are all key components of successful AI deployments.

Below, you can hear the entire episode:

Visitor: Rad Desiraju, Microsoft’s Director of Worldwide Industry Advisory

Knowledge of Digital Transformation, Manufacturing, and Industry Advisory

Brief Recognition: Rad is Microsoft’s global industry advisor for manufacturing, assisting business clients in implementing cutting-edge technologies like edge AI and digital twins driven by artificial intelligence. He frequently presents at interoperability and standards-focused events including SEMICON West and SEMI’s “Digital Twin” workshops. Rad is a well-known thought leader that works with industry partners to provide firms with proactive operational modernization advice.

Mike Geyer, NVIDIA’s Head of Digital Twins, is the guest.

Proficiency in Digital Twins, Robotics, Industrial AI, and Platform Strategy

Brief Recognition: Mike is in charge of NVIDIA’s industrial AI projects, which promote the creation and uptake of manufacturing simulation tools, digital twins, and libraries. He brings decades of domain experience from his previous positions at Autodesk and Caterpillar. His most recent LinkedIn articles emphasize how NVIDIA is working with big manufacturers to use physical and industrial AI to revolutionize.

Using 3D Digital Twins To Advance Manufacturing Intelligence

Rad Desiraju lays up three distinct stages to set the scene for the development of dashboard production over the past few decades. His explanation of this history provides a range of manufacturers’ positions in the global economy with regard to the level of sophistication of their dashboard deployments:

- dashboards for diagnostics that display the events.

- operational dashboards that display current events.

- dashboards for simulations that let producers investigate possible outcomes in different scenarios.

While many manufacturers have implemented monitoring dashboards to view factory data, Rad notes that the majority are still only able to model “what-if” situations in real time, and most are stuck at the first two stages.

This is due to the fact that meaningful simulation, the type that aids in leaders’ proactive decision-making, necessitates infrastructure capable of accurately interpreting data and access to dependable, standardized data:

The development platform we’re working on with Omniverse is one example; it enables you to use OpenUSD to integrate data from various sources and create a 3D collaborative environment.

At this moment, the things we have been discussing and dreaming about for the past two decades are becoming a reality thanks to the convergence of technology, acceleration, data platforms, and analytics. The rate of change seems to be picking up speed very quickly.

– Rad Desiraju, Microsoft’s Director of WW Industry Advisory

The majority of product producers have been utilizing 3D product design since the 1990s, according to Mike Geyer, who elaborates on the idea. Applying the same degree of dimensionality and analysis to the production floor is the next stage.

Mike claims that without the need for actual trial and error, simulation dashboards enable the dynamic modeling of whole production environments, including rerouting supply lines, improving material staging, and modifying the product mix.

As computing shifts to the cloud and becomes more scalable, back-end power is also developing very quickly. Facilities for manufacturing are not 2D. You could bump into something that you wouldn’t see on a 2D dashboard when you’re walking about.

These are three-, four-, or five-story buildings with intricate dependencies that affect not just how objects move up and down the floor but also horizontally. If you are trying to train physical AI, you must be able to replicate the real world. This is where the open development platforms, GPU acceleration, and Microsoft’s ability to piece everything together are what’s enabling the status quo to shift so swiftly.

— Mike Geyer, NVIDIA’s Head of Digital Twins

As Mike explains, the ability to remotely evaluate and enhance plant performance is revolutionizing manufacturing decision-making. Businesses can now use real-time simulation to drive just-in-time manufacturing methods rather than relying on demand forecasts.

Mike goes on to discuss how automation and artificial intelligence (AI), especially the emergence of humanoid robots and AMRs (Autonomous Mobile Robots), are making these improvements possible by assisting manufacturers in modeling both human and product workflows. One important result is safety, particularly in high-risk settings where robots might help with repetitive or hazardous activities.

Constructing Interoperable, Scalable Infrastructure

Implementing AI-powered simulation and digital twin systems is an infrastructure challenge that extends across the cloud, edge, and actual industrial environment. This is a key takeaway from both speakers.

According to Rad, successful deployment requires three different computing environments: one for training AI models, one for simulating digital twins, and one for performing inference at the edge, which is frequently done on actual robots or PLC systems. For real-time insights to be generated, each environment’s computation and latency requirements must be flawlessly coordinated:

In order to tackle this issue, we attempt to investigate three vertical archetypes. The first is creating a contemporary data architecture, also known as a “data lake,” which is crucial to have.

It combines all of the structured data into one place and lays the groundwork for you to speak with the data and ask questions about it in natural language. It is known as structured data extraction, and it is the first pillar we constructed. Document intelligence is the name of the second one. Making them interoperable is the third step.

– Rad Desiraju, Microsoft’s Director of Worldwide Industry Advisory

Specifically, edge computing is essential. Both speakers stress that manufacturers need to analyze data as close to the source as feasible and minimize latency for digital twins to be effective. To handle compute-intensive applications like 3D simulation and sensor data fusion, this entails implementing containerized infrastructure and GPU acceleration, both on-premises and in the cloud.

Mike points out that the ability to appropriately scale GPU performance to each unique application is a crucial differentiator of the NVIDIA-Microsoft relationship. Manufacturers benefit from this flexibility by avoiding overprovisioning, cutting expenses, and accelerating time-to-value, particularly in sectors where even a few minutes of downtime can cost millions of dollars.

“The ability to make that computation scalable through these open development platforms that enable our development ecosystem to create digital twins using their own tools that are enhanced by some of our parallel compute and accelerated GPU capabilities is one of the things we’ve been really working on a lot with our partners, like Microsoft.”

— Mike Geyer, NVIDIA’s Head of Digital Twins

Mike continues by explaining how the proper infrastructure is necessary to support manufacturing’s status quo methods, such as modernizing warehouses every few years.

Rad responds that a clear business outcome must be the starting point for any discussions regarding these degrees of digital transformation and the infrastructure required to achieve them. Any AI implementation must be focused on specific, organization-critical goals, such as increasing throughput, lowering operational costs, and enhancing safety, among other manufacturing use cases.

Teams can then adjust platform architecture, computation requirements, and data standards appropriately. “Yes, digital twins are beautiful,” says Rad, “but the most important thing is to ask: What is the business value you’re trying to solve for?”